“Collecting data from CNC machines is as easy as 1-2-3,” said no engineer ever.

Collecting machine data is more than frustrating -- it's time consuming and expensive. That doesn't mean your company has to skip older equipment or machines with proprietary protocols.

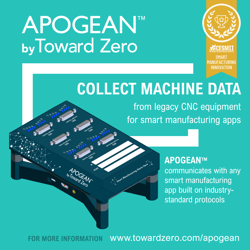

Apogean™ makes collecting data from CNC machines quick, easy, and inexpensive.

If you're unsure what approach is right for your company or specific machines, our machine connectivity engineers and smart manufacturing experts can help you design an effective and efficient strategy for your data collection needs.